STANLEY WHITE BOAT WORKS

Custom Center Console & Yacht Tenders

Designed, Engineered & Hand Built.

Serving South Florida from Okeechobee to Key West. Lifetime Transferrable Warranty. Proprietary step bottom for comfort speed and economy with Tow-Specific Hull Integration

WELCOME TO STANLEY WHITE BOAT WORKS

Luxury Yachts Designed, Engineered and Hand-Built since 1984.

The High Performance Multi-Step Hull

WHAT iS MULTI-STEP HULL?

We start with our hull design procedure by giving the hull a mission , in the case of the former RYBO RUNNER cousin, a high speed (50 miles per hour plus), stable but soft riding (a good compromise between tenderness and stability , 20 degrees dead rise ), a fine entry forward (requires aft center of gravity, 40% from transform), sufficient bow overhang (produces bow flare for a dry boat), totally developed hull lines (no flat side , sharp corners, or straight lines), wide beam to length ratio (wide passage ways around the center console) and super fine too ling (to produce a smooth and high gloss finish with no waves).

With all this accomplished, we now had a set of hull lines that would produce an exceptional performing mono-hull (no steps). How do we make better an already successful performing hull? Simple. reduce the wet surface, therefore reducing the drag. How? sculpture steps at pre-calculated positions resulting in three angle of attack planning surfaces stiffening lateral and longitudinal stability while maintaining a level trim.

The multi-step hull has only positive features, without any negative side effects.

WHY DID WE CHOOSE TO BUILD A STEP BOAT?

If you knew what we know about the comparison test results between the mono hull (no steps) and the multi-step hull, you too would be left with no other choice; go with the step hull.

Any time you reduce the wetted surface, you automatically reduce the drag and increase efficiency resulting in higher speeds with less horsepower and less fuel consumption (this can be compared with a mono sailing hull and the twin hull catamaran. There is just no comparison – less wetted surface, less drag and much more speed in the same wind).

Amphibian and float aircraft could not get up to flying speed without their “step bottom” on the hull and floats. The “take off’ procedure requires the pilot to put the aircraft “on the step” which reduces the wetted surface and therefore, it’s drag, and permits the aircraft to obtain flying speed.

WHY ARE NOT ALL HULLS ADVANCED TECHNOLOGY DESIGNED MULTI-STEP CONCEPTS?

Well, step hull design Is not yet in the textbooks. Although outboard, inboard and Gold Cup racing step hulls have been winners for over 60 years, wooden step hulls were very expensive to build and the advanced technology concept is only known to a handful of designer’s current in the state of art. Therefore, few pleasure craft or sport fishing craft made the scene except for limited custom concepts. Fiberglass construction has changed all that. No w a step hull can be con structed in Just 10% more hull time than a mono hull Nov. it’s production feasible and cost effective.

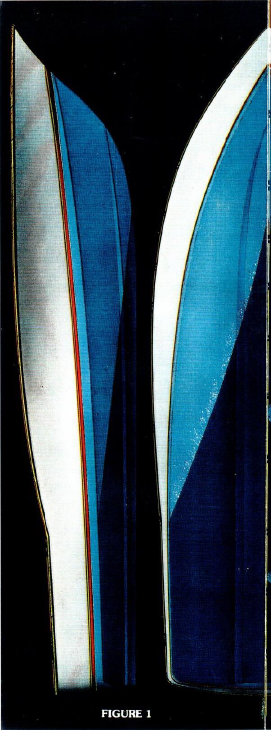

A PICTURE IS WORTH A THOUSAND WORDS.

Figure l is the multi-step hull without the sculpture d steps. This is how we stan our step hull design procedure.

The dark blue area represents the wetted surf ace oi the non-step hull at 40 MPH cruise. Lots of wetted sur face therefore lots of drag requiring lots of horsepower to overcome and consuming lots of fuel.

Figure 2 1s the same hull with the steps sculptured· to the hull bottom at precalculated locations based on many years’ experiences in multi-step design. and the computer tells us what angle to use on the planning surfaces to have the hull meet its design mission.

STEP HULL VENTILATING SYSTEM:

Air (white arrows) must replace the area of the reduced wetted surfaces (usually step hulls have notches at the steps on the chi ne). This type of system is natural step ventilation and except for non-traditional aesthetic qualities, this Is the best way to go). Beca use the RYBO RUNNER was designed solely as a sport fishing boat and we wanted to induce as much lateral stability as possible , we chose not to interrupt the chine and to interrupt the chine and to build ventilation boxes inside the hull to permit air to flow through the vent box to the mid and aft step planning surfaces without affecting later al stability as compared to the monohull (no steps ).

HULL INTEGRITY

Now the competition raises its ugly head and says,

“but they have holes through the sides and out the bot tom of the hu ll.” True, but we have a double bottom with conduit in between the two bottoms so that if you cut the first bottom out. you cannot invade the integrity of the main hull. This advanced construction method of the RYBO RUNNER is only one of many new improvements from 1988.

CONCLUSION

The angle of attack on the aft and mid steps planning sur faces controls the area of the reduced wetted sur faces and therefore, the drag while creating lift forces capable of carrying very heavy loads while maintaining level longitudinal trim. Th e hull comes out of the hole without transom squat and remains on plane at a slow

12 miles per hour. Comparing the wetted surface area of the mono hull against that of multi-step hull’s 40% less wet surface area, simply tells the story. ” Less wetted surface produces less drag requiring less thrust to push the hull at the same speed, both hulls being the same weight.”

The multi-step hull’s time has come!

OUR SERVICES

Superior Tooling & Construction Methods

- All hulls are hand laid and we use high quality 3610 biaxial cloth and vinyl ester resin.

- Gelcoat is used doubling the industry norms for longevity.

- Reinforced proprietary hull panels, stringers and specific towing bridle locations for strength.

- All metal fasteners thru-hull are secured with metal backing plates and drilled and tapped for

longevity and strength. - Custom engine mounting and beefed up 5″ transoms with aluminum backing plates standard.

Build time, depending on specs is 3 to 6 months. Many options are open for your preference:

- Single or twin transom doors/ dive door

- Custom fuel tankage

- Bait wells and tanks

- Showers and day-berth in console

- Custom rod locker

- Custom colors/stripes

- Hardtop, towers and canvas/bolsters

- Helm seats to suit with tackle center

- Custom lighting, lounges, chairs

- Full electronics

- Engines Mercury/Yamaha or Suzuki

- Seakeeper optional

- Custom Florida built Bad Boy trailers

OUR STORY

About Stanely White Boat Works

We are committed to providing no-nonsense professional services …….. whether building you a new

custom boat, finding an exceptional pre-owned boat, or servicing, customizing or completely renovating

your existing vessel.

Our sales staff has extensive experience and a well-deserved and outstanding reputation in the yachting industry.

SW is an experienced and long-time builder, following some of the great boat building traditions with modern upgrades and industry leading manufacturing.

Quality is our goal and we back it up with a LIFETIME HULL WARRANTY – even transferrable to subsequent owners. That’s how confident we are in our product and our knowledgeable owners. No one else offers this warranty perk. Feel great about building a custom boat with a lifetime warranty.

We specialize in sport fishing center consoles and large boat tenders for towing. We are active in the brokerage and used boat market with experienced sales agents with exceptional knowledge and

integrity. Are you ready for a change? We consider all trades and SWBW also produces a simple 18′ flats boat for special order. We can make them match each other or match your primary tow vessel.

Call us today for more information.